- Filter by

- Categories

- Tags

- Authors

- Show all

- All

- 17-4 stainless steel

- 3D metal printing

- 3D metal printing companies

- 3D metal printing service

- 3D Printing

- 3D printing companies

- 3D Scanning

- 3dprinting

- additive direct manufacturing

- Additive Manufacturing

- additive manufacturing companies

- additivemanufacturing

- Aerospace

- aerospace additive

- aerospace additive manufacturing

- AS9100

- Auto Racing

- C-103

- c-103 additive manufacturing

- CMM

- Collector

- Crucible

- deep draw

- Defense

- direct metal deposition

- direct metal printing

- DMP

- Exhaust Collector

- High Performance Turbo

- hot gas valves and manifolds

- Inconel

- inconel 718

- ISO 9001

- Laboratory Crucible

- Labware

- Molybdenum

- molybdenum crucibles

- nickel

- niobium

- niobium crucibles

- Niobium printing

- post boost control system

- post-processing

- press forming

- Prototype

- Prototyping

- proX 200

- ProX 300

- Race Car

- rapid prototyping companies

- rapid prototyping services

- refractory metals

- Rocket Engine

- Space

- stainless steel 3D printing

- strategic missiles

- Tantalum

- tantalum crucibles

- Titanium

- titanium crucibles

- tungsten crucibles

- Turbo

- zeiss contra

- zirconium

- zirconium crucibles

June 24, 2016

Categories

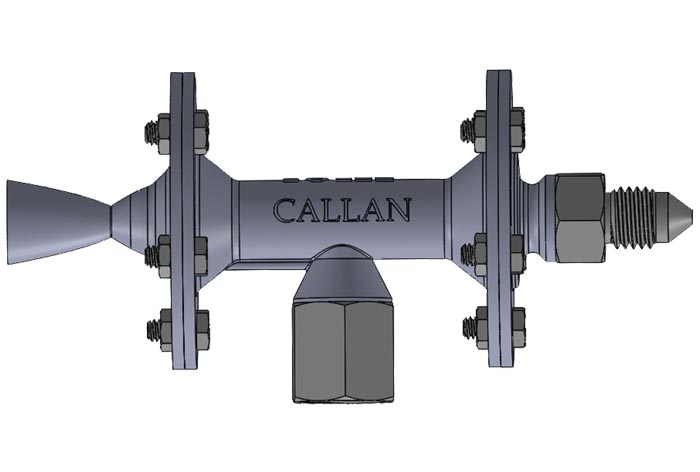

CubeSat Engine Successfully Printed | Aerospace Additive Manufacturing Metal Technology successfully printed and processed its latest initiative in aerospace additive manufacturing – the engine for the CubeSat, Triteia. This engine, named Callan, is the final piece of a project that MTI has been working on with UC San Diego student organization, the Students for the Exploration and Development of Space […]

Do you like it?

April 4, 2016

Categories

Another Step Forward In Aerospace Additive Manufacturing Metal Technology (MTI), has partnered with University of California San Diego student organization, Students for the Exploration and Development of Space (SEDS). This partnership between MTI and SEDS was formed so that MTI could contribute aerospace additive manufacturing services to aid in the construction of Triteia – a semiautonomous, chemically propelled 6U CubeSat competing […]

Do you like it?

November 11, 2015

Categories

MTI Utilizes Aerospace Additive Manufacturing Expertise In NASA Partnership Metal Technology (MTI) is collaborating with NASA Johnson Space Center (JSC) to develop the next generation of rocket engines through aerospace additive manufacturing. Few organizations are as busy integrating 3D metal printing into their engineering and design work as NASA. NASA currently has multiple business units working their own projects as […]

Do you like it?

November 3, 2015

Categories

MTI To Assist In The Production Of Next Generation Rocket Engine MTI is proud to announce that they have partnered with the University of California San Diego chapter of Students for the Exploration and Development of Space (SEDS@UCSD) to sponsor the students in their next round of research regarding the use of aerospace additive manufacturing. This partnership between MTI and […]

Do you like it?

April 24, 2015

Categories

NASA Achieves Historical Innovation For Aerospace Additive Manufacturing NASA Marshall Space Flight Center in Huntsville, Alabama has reached the brink of aerospace additive manufacturing innovation by producing a 3D printed, full scale, copper rocket engine part. The build took 10 days and 18 hours to complete, and incorporated 8,255 layers of copper powder. Here at MTI, we love to see […]

Do you like it?